Liners

7 min read

The teat cup liner is the part of the milking machine that touches the cow's teat, significantly affecting milking performance, udder and teat health. The page discusses the importance of selecting and maintaining the right teat cup liners to improve animal health, increase milking efficiency, and reduce stress on animals. It provides guidelines on choosing liners that fit various teat shapes and sizes, ensuring efficient milking without causing discomfort or injury. Furthermore, the page includes details on proper cleaning and maintenance, and factors to consider when replacing or changing liners to make sure they suit your herd and milking equipment.

The teat cup liner is the only component of the milking machine that comes into contact with the cow's teat. It has a large influence on milking performance, udder and teat health.

Benefits of the right selection and maintenance of teat cup liners include:

A good teat cup liner will:

Choosing a liner is a compromise. One must consider the milking machine, its settings and very importantly, the cows.

Ultimately, if the proposed liner fits the milking equipment, it can be compared in the milking performance of your cows alongside other liners aiming for fast, efficient milking without any 'ill' effects.

Even then, a better performing liner may warrant some change in equipment.

Liners may be made in either 1 or 2 piece designs. A 2 piece liner has a separate short milk tube. Most New Zealand farmers choose 1 piece moulded liners, as they are easier to assemble and simpler to change when due for replacement.

Liners are commonly described as wide, medium or narrow-bore depending on their internal diameter relative to the average teat size for a given herd. A wide-bore liner is at least 1 mm larger than the mean teat diameter measured at the mid-point of the teats. A narrow-bore liner is at least 2mm smaller than the mean mid-teat diameter of the herd. Talk to experienced suppliers and technicians to help decide on a size that suits your operation.

The majority of New Zealand liners have a cylindrical barrel, but square, triangular and oval designs are starting to appear on the market.

An array of different liners.

The appropriate effective length (EL) of the liner depends on the range of teat sizes in a herd, and on the liner bore (see table below). Wide-bore liners need a longer EL because the teat penetrates further into them.

NZ Milking Pump Trade Association (MPTA) technicians have access to tables showing the effective lengths of different commercial liners and how to measure the effective length.

Correct mounting tension is essential to give proper pulsation squeeze on the end of the teat. Liner tension is determined by the size of the liner in relation to the shell. Conventional rubber liners should have 5% to 16% stretch. Liner tension can be checked by measuring the shell, then the tension ring where it fits the shell.

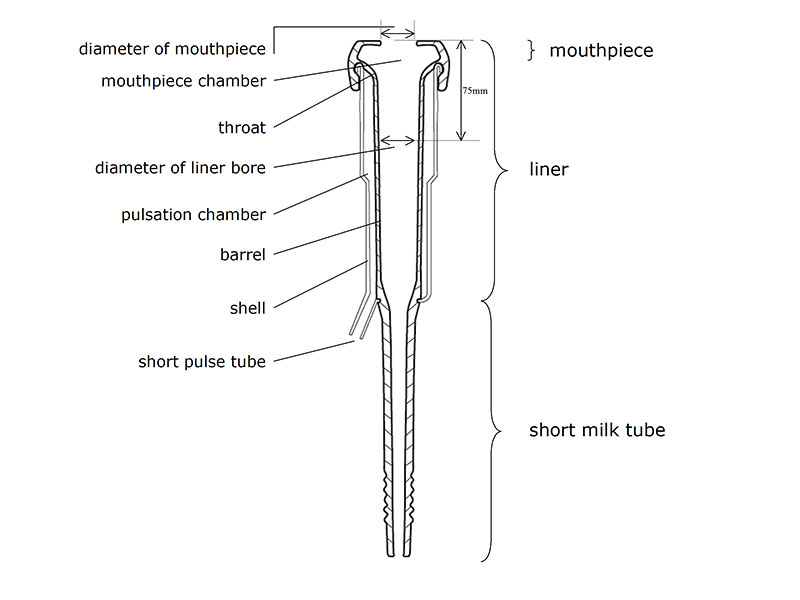

Anatomy of a teat cup (liner and shell).

A cross section of different liners to show the length, size and shape.

| Liner bore at mid-barrel (mm) | Minimum effective length (EL)(mm) |

| 21-22 | 135 |

| 23-24 | 140 |

| >25 | 145 |

Measuring liner stretch

Changing your liners when they are worn out, or if they do not fit the shell properly, will make money not cost money. The purpose of this calculation is to decide whether a liner is capable of working effectively.

NB. This is only one of four checks needed to decide whether or not a liner is worn. See later.

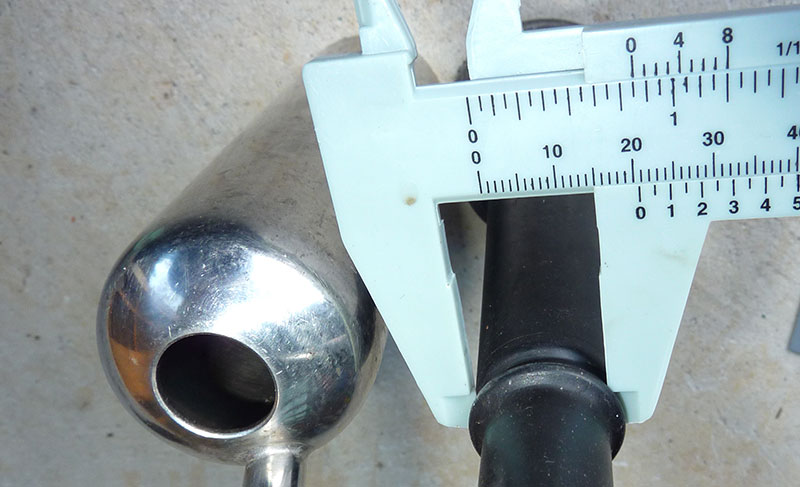

Procedure: You will need the template below, a ruler, your shell, a liner and some callipers. Measure the following and write the results down:

| A | Shell length. | A= | |

| B | Liner tension length. | B= | |

| C | Outside diameter of liner tension ring where it passes through shell hole. | C= | |

| D | Inside diameter of shell hole. | D= | |

| Calculations | |||

| Liner stretch calculation = ((A-B)/B) x 100 | |||

| 5-16% is Ok. | |||

| Liner constriction calculation = C - D | |||

| 2-5 is Ok. | |||

A good cleaning system with regular hot alkaline washes is necessary to maintain liner performance. Poor cleaning can result in faster surface deterioration and bacterial growth.

Liners should be removed from jetter wash systems after cleaning. Leaving liners on any type of jetter between milkings will not allow the system to dry and can increase bacteria growth. Liners left hanging on button style jetters can distort the mouth-piece, increasing slip and reducing liner life.

Liners should not be re-tensioned by pulling them up to a second tension ring after half of their life, they should be replaced as they are worn out. Re-tensioning will only improve milking for a short time. Over-tensioned liners may lead to teat end damage.

Liner slip is inconvenient and can have a negative impact on milk quality. It is often due to causes other than the liner itself.

| Factor influencing liner slip | Action |

| Unsuitable choice of liner | Select a liner which suits your herd and their teat size. |

| Incorrect vacuum levels | Maintain vacuum levels in the proper range for your milking system. |

| Inadequate vacuum pump capacity and line sizes, excessive system leaks, long sagging milk tubes | Be sure all components of your milking system are properly sized. Keep milk lines as low as practical (always < 1.8m). Shorten the stainless steel part of the long milk tube to end 500-600 mm above the cow platform. |

| Poor regulator, or variable speed drive response | An insensitive vacuum regulator (or variable speed drive) can result in extreme vacuum fluctuations. Keep it clean and serviced. |

| Poor cluster alignment | The cluster must be well aligned with the udder to achieve a good seal between the teat and the liner. Shorten the long milk rubber so that it doesn’t sag, helping the cluster to hang evenly. Don’t make it so short that it pulls the cluster out of alignment. Shift the milk line if it is not possible for the clusters to sit squarely under udders. |

| Twisted liners | Liners that are twisted inside the shell prevent the teat from entering the liner properly, resulting in a poor vacuum seal. Make sure the index mark on the liner head and short milk tube are aligned. Take care liners are not twisted when placing cups on jetters. |

| Light quarters | Light quarters often cause air leaks between the teat and liner. |

| Cluster weight | Check that the cluster weight is not too heavy. |

Factors influencing liner slip and recommended action

Liners should be replaced as they are worn out, not re-tensioned. Re-tensioning will only improve milking for a short time and over-tensioned liners may lead to teat end damage.

When changing the liner type it is important to get a good match between liners and cup shells, and also with the rest of the dairy set up.

Most milking equipment companies provide guidelines for correct matching of their own particular brands, and technicians usually have access to a collated set of MPTA specifications from different companies.

Visual checks

Do monthly checks of liners and short milk tubes for cracks and splits. Early detection of split liners can be improved by fitting clear (normally PVC) short or long pulse tubing.

Check the liner for perishing, cracks and splits.

Performance checks

Regular occurrence of any of the following may highlight an issue with teat liners or milking machinery:

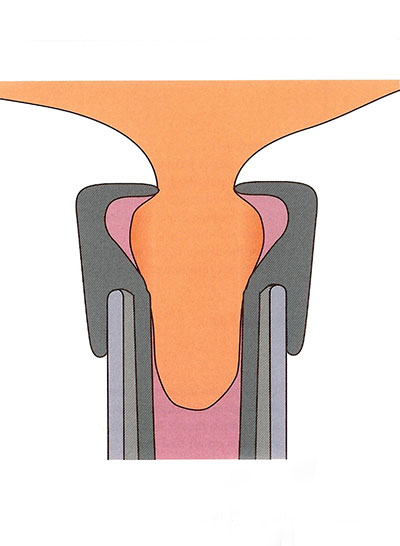

A teat ring caused by a vacuum in the mouthpiece chamber.

This ring being on constant vacuum is responsible for holding cups on. Unusually pronounced rings on cows' teats indicates overmilking or too high a vacuum level.