Automatic milking systems

19 min read

Robotic milking systems also known as an Automatic Milking System (AMS) lets cows choose when to be milked by a robotic system without human help. It has a robotic arm and an identification system. When a cow enters, it's checked if she's due for milking. If yes, the machine milks her, collects data and sends the milk to tanks. Successful AMS needs good farm management and works best when motivated by feed. For your farm, consider phone and broadband coverage, the landscape, proximity to servicing, and if you're tech-friendly. Setting up requires planning farm layout, water access, dairy design and smart grazing management. With AMS, managing pasture efficiently is key. While your grazing system remains, the method changes, promoting voluntary cow movement.

An Automatic Milking System (AMS) is a generic term used to refer to automated systems that complete the whole milking process without the direct assistance of milking staff.

Automatic Milking Systems are often referred to as 'robotic' or 'voluntary' milking systems.

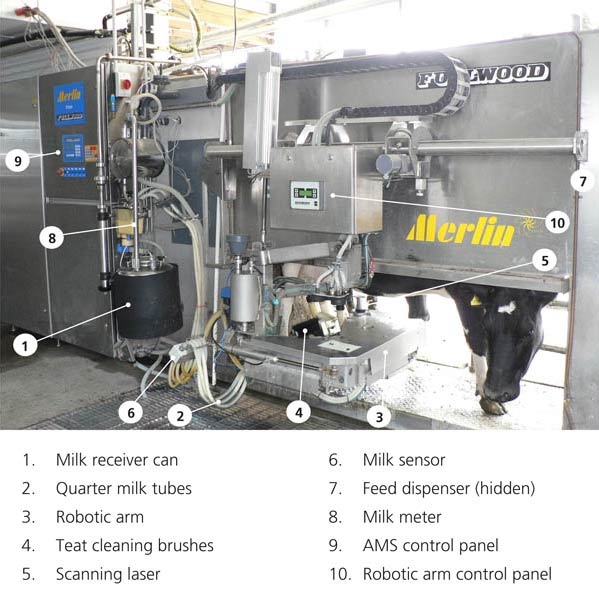

'Robotic' refers to the robotic arm that performs key functions of the system (eg cup attachment). The term 'voluntary' is used because cows can choose when they want to be milked.

They typically consist of a milking stall or crate with a robotic arm that attaches the teat cups to each cow without human intervention, an electronic identification system, and a milking machine.

An AMS still requires all the same basic farm management as a conventional system. The processes are just different in order to achieve the final product.

The cow enters the crate and is identified via a tag strapped to her leg, around her neck or in her ear. The software determines if the cow has milking permission. If she is not due for milking the front gates open and the cow is released. If she is due for milking the teats are cleaned (optional) and the teat cups attached, one at a time. Teat cups are removed based on flow from individual quarters. While milking, the cow may be offered a concentrate (meal, grain, molasses). Milk is diverted to separate tanks if requested by the operator using the software settings, otherwise it enters the bulk or temporarily a buffer tank. Various data is collected on both the cow and milk quality. These can include live weight, quarter yield, quarter conductivity, colour, fat, protein and SCC.

Main features of an AMS

Automatic milking relies on cows volunteering for milking in the AMS and distributing these milkings throughout 24 hours. The main motivator for cow movement around the farm is feed, either fresh pasture and/or concentrate in the AMS. Most AMS farms are set up with two or three new areas of pasture available to the herd daily. Cows access pasture after visiting the AMS or can be diverted directly to the new pasture if milking permission is not granted.

Is there reliable mobile phone coverage and broadband available? The AMS requires broadband for remote servicing and phone coverage is essential so you are alerted to technical problems at the dairy.

How far away do you live from the dairy? You will need to attend to alarms that can occur anytime in 24 hours

Is the farm hilly, long and narrow or does it comprise fragments of land with roads in between? Experience to date suggests that walking distances of up to 1km present few issues for cows. It is not necessary for cows to be able to sight the dairy from all paddocks however the farms currently in operation in New Zealand are generally flat to rolling. As the land becomes steeper it is likely that more intervention will be required.

Is there a service provider within 2h of your farm and will they guarantee support within this time frame? Don't forget that AMS operate 24 hours a day and require 24 hour support.

Is your shed due for renewal? A conversion to AMS is capital intensive, have you got the most from your existing dairy?

Is the current site relatively central within the farm? The ideal location for an AMS dairy is near the middle of the farm so that walking distances are minimised, however the cost of installing services such as power will be higher the further from the road or current dairy.

What farm system is best suited to automatic milking?

Dairy farms in New Zealand are classified as system 1 to 5 based on the level of bought feed (including grazing off) used and fertiliser applied. There are farms from every system operating AMS in New Zealand. In general the higher the level of imported feed the easier it should be to implement and get the full benefit of automatic milking and individual cow feeding, particularly if supplementary feed is offered at the dairy. All systems require good grazing management to encourage good cow flow and optimise pasture production and utilisation.

A small level of concentrate is generally required to maintain cow flow through the milking stations although there is one farm in New Zealand operating successfully with only grass and no feed in the AMS.

The DairyNZ research farm (Greenfield project) successfully operated within the criteria of a system 2 farm. Within conventional systems emphasis is on milk production per ha. This is equally applicable to automatic milking, however milk production per milking station is another very important performance indicator for system profit. The focus should be on optimising the utilisation of the automatic milking system, whichever farm system is operated.

How many milking stations do I need to milk my herd?

The most common automated milking systems milk one cow at a time but operate 24h/day. The number needed to milk a herd will depend on how often you want the cows to be milked, the peak yield of the herd and what level of utilisation of the milking stations can be achieved. Typical numbers of cows per AMS are 60 to 90.

Each milking has a fixed set-up time, so the aim is to increase the yield per milking by increasing the milking interval but not to the extent that per cow production is compromised.

Is a seasonal or split calving pattern more suited to AMS?

Both can work well in an AMS farm. While split calving better utilises the AMS through the year the decision should be based on economics and the profitability of winter milking needs to be carefully evaluated. Seasonal calving places additional pressure on the AMS about four weeks into calving. This is because of the washing time required between colostrum and mastitis cows. Plan the dairy layout so that colostrum cows can be drafted to a particular robot which avoids taking up time on the other machines.

Do you expect to increase herd size in the short to medium term?

Consider the AMS capacity and leave space for further robots in the dairy design. Remember as the herd gets larger the economics favour conventional milking as more cows can be milked in the same facility whereas more cows will usually require more robots on an AMS farm.

Will AMS maintain your system productivity?

The association between pasture utilisation and milk yield are important in both conventional and automatic milking, however the emphasis on the two within automatic milking has additional benefits to the system (i.e. cow flow). This means that an effective AM farm is a highly effective conventional farm. DairyNZ research has produced results from a low input system (2.5% of feed imported) that are equivalent to a ‘best practice’ conventional system.

Is the business strong enough to support the finance associated with AMS milking?

For more information see:

In addition to the technical performance of the AMS and the design of the dairy and grazing system, a key factor in a successful AMS installation is the operator.

While it is important that the user is comfortable with technology and is not overwhelmed by hardware and software, it is essential that they are capable of taking a step back and trusting the technology. Frequent intervention and constant adjustment to the settings of the AMS and interfering with the cows will reduce attachment rates and overall performance.

It is essential the operator recognises the importance of regular maintenance and cleaning. It is also important that the operator recognises that while the AMS will harvest milk from the cows, the daily management of the herd is still required.

AMS is not a substitute for good farm management practices.

Consider these questions for yourself and potential staff:

Information about setting up your farm for AMS including farm layout, races, water, dairy design and grazing management.

There is no single correct way to lay out an automatic milking system (AMS) farm. To minimise walking distance, ideally locate the AMS near the centre of the farm.

As the whole herd does not walk along the race at once, there can be uneven wear on an AMS farm.

Areas close to the dairy and AMS can get soiled easily and will likely require more frequent maintenance. Ensure they are wide enough to make maintenance an easy task.

Position gateways at the end of the paddock closest to the dairy as this is easier for cows to exit without assistance.

Do not limit cows' access to water. Ideally it should be available at multiple locations on the farm. It is not necessary to have water in each paddock. However, depending on distance it may be in laneways, at the dairy, in the paddock - or all three.

There are two main considerations when designing the dairy: cow flow and people comfort. Both are important for an efficient operation. Talk to the suppliers for different options.

Successful automatic milking goes hand in hand with excellent pasture management, which is good news given New Zealand’s pastoral farming systems. This is because voluntary cow movement is largely determined by pasture availability. Looking at post-grazing residuals, along with production and milking frequency data available from the management software, provides a key gauge of feeding level, ensuring pasture harvested is maximised.

To achieve a >70% utilisation rate with approximately 80-90 cows per milking station, without extended cow waiting times, requires good control of cow traffic. This is achieved using drafting units or selection gates, positioned either in the dairy or along the raceways remote from the dairy, which automatically allow targeted cows to enter a new grazing area, be returned to older pasture or sent to the dairy for milking. Typically two or three new areas of pasture are available to the herd daily, with one of these occurring near midnight to ensure the milking stations are kept busy during the early morning hours.

Profitable operation of pastoral dairy systems is based on the correct feed allowance per cow that will result in optimal/profitable feed conversion efficiency per cow and hectare. Research indicates this is in the vicinity of 80 – 90kg LWT/t DM.

Grazing systems have been developed to utilise pasture efficiently and allocate feed to the herd in a manner that balances cow production and profit. There are grazing ‘tools’ in use that enhance this (e.g. pre-graze mowing, returning cows to a grazed area until the desired residual is achieved), and pastoral AMS utilises many of the same ‘tools’ but with a few extras.

Within a batch milked system control over access to grazing (duration, area, mass, herd size), and milking frequency (herd scale twice a day, once a day (or combinations within the herd) are directly imposed in the day-to-day operation of the farm.

By contrast automatic milking relies on voluntary cow movement from the grazing area to the AMS. Control of the operational running of the farm is then a shared function between farm staff and the cows themselves. It is important that rotational grazing is balanced to induce cow movement. To achieve this at least two and preferably three allocations of fresh pasture (or other feed) are offered each day.

Many people believe that all grass dairy systems cannot work with voluntary milking. DairyNZ research has shown that with appropriate cow traffic systems in place 24h milking can be achieved with just 2.5% of the diet concentrate fed through the AMS and over 13 T/ha DM can be harvested from the farm.

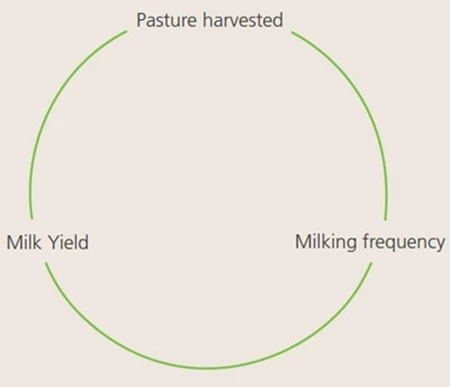

Cyclic pattern of pasture harvested, milking frequency, and milk yield within an AMS.

Feed availability is a prime motivator of cow movement, in particular pasture residual mass is a critical factor that motivates the cows to move. Voluntary cow movement is necessary to obtain a desired milking frequency, which affects milk yield. The effect is a cyclic pattern of linked events that will determine productivity of the system. See image above.

As pasture residual levels increase the cows will reduce voluntary movement and therefore milk less frequently with the flow on affect in reduced yield. This creates a reduced feed demand, which in turn will result in higher residual mass level. The direction of this cycle is critical for pastoral AMS.

A flexible approach to manual cow movement has a positive affect especially during periods when pasture supply exceeds demand. Typically, cows remaining in a grazed area would be manually moved from that break twice daily. Adopting a flexible approach to the timing of these manual moves can allow for greater control over post-grazing residuals and therefore intakes. There are other flow-on benefits in terms of increasing milking frequency and AMS utilisation. The timing of manual moves is determined by cow traffic patterns, paddock location, time of day and grazing residual.

Voluntary milking systems are reliant on motivation within the system for cow movement. Milking robots have a feed bin at the front of the stall in which meal can be dispensed. The introduction of imported feed requires no labour input as the feed is allocated to the cow as she is milking. As the feed allocation at the AMS increases so does the motivation to ‘visit’ the AMS.

The 1-5 system definitions used by DairyNZ are based on the feed imported, and a system that is totally reliant on pasture, as the feed supply, will require efficient pasture management skills. DairyNZ research has demonstrated that the system is effective with 97.5% of the diet from pasture. As the quantity of imported feed increases the emphasis shifts from intense grazing management to ration-balancing skills. In essence, the same factors that are applied to a conventional system when increasing the feed input (i.e. importing feed) will apply to an AMS. With the exception that the infrastructure required is reduced (i.e. feeding concentrates ‘in bail’ is an existing facility).

A detailed timeline to start-up or calendar of events helps everyone involved anticipate the challenges and makes the transition from conventional farming to an AMS free from unpleasant ‘surprises'...

People

Herd

Facilities

Facilities Plan the construction and/or renovations needed to accommodate the AMS units.

Ensure that all required services are available eg: phone line for robots to generate alerts, suitable power supplies - check phase and voltage with manufacturer.

Ensure the “old” milk harvesting equipment is maintained properly until its decommissioning.

Other Considerations

It is not worth the heartache of starting the AMS dairy with a high level of mastitis. It is false economy to reduce the frequency of liner changes or cut back on machine maintenance or servicing of the conventional dairy leading up to the AMS commissioning.

It may also be worth developing networks with other AMS users to learn from their experiences.

Your AMS supplier should be able to put you in contact with other farmers that have installed AMS units.

People

Herd

Facilities

Other Considerations

Pre-selecting cows based on udder conformation is not recommended.

Different brands of machines cope with different udder conformations so it is not possible to make general, blanket recommendations. Instead, bring all types of udders to the AMS dairy and let the machines tell you what conformations are not suitable. This saves time and the unnecessary culling of some cows.

People/Facilities

Read your AMS manual and become familiar with:

Other Considerations

It is worth being aware though that there may be a small proportion of cows whose udders are not suitable – just as is the case in any dairy operation.

Where possible ensure that all aspects of the new installation are completed prior to introducing the cows into the system. Incomplete buildings, laneways and/or surrounding infrastructure will make your life more difficult and introduction more stressful for the cows.

Herd

People

Other considerations:

A single robotic station is in the range NZ$225-275K. This varies across manufacturers and according to how many machines are required.

Each AMS will milk 60-90 cows, depending on milking frequency.

A single station can theoretically achieve up to about 160 cow-milkings in a 24 hr period.

The cow capacity per robotic station therefore depends on how frequently cows are required to be milked and on milk yield. On grazing farms in practice, this is usually about 130 - 150 milkings per day.

Regular preventative maintenance is required, with fortnightly farmer services (mainly checking equipment) and less frequent services completed by company technicians. It is important to realise that while it is no longer necessary to milk the cows staff must be able to be contacted via pager or cell phone to attend to any alarms - which could occur at any time.

Some brands have the ability to attend to some alarms remotely and reset the milking station using a laptop computer.

Automatic milking changes the tasks that people are required to carry out on-farm. Many routine jobs remain, but the timing of those jobs is more flexible.

It is still necessary to fetch cows that don't report for milking; set up paddocks for grazing; fill chemical containers; complete regular maintenance on the AMS, monitor reports and keep the AMS clean.

It is no longer necessary to move the whole herd to the shed for milking or to put cups on cows.

Automatic milking has exciting potential for owners managing multiple farms. Because of the flexibility in work routines and low physical demands of the tasks that need to be carried out on an automatic milking farm, staff and work routines could be scheduled or staggered across farms allowing for more efficient labour use and more respectable hours of work. One person could be on-call to attend out-of-hours alarms for multiple sites.

A higher level of skill will generally be required for automatic milking farms and good animal husbandry skills are essential. Staff must be able to interpret information provided by the systems in order to make informed decisions regarding cow health and feeding levels.

The importance of people in the success of automatic milking operations should not be underestimated. Not all people will be suited to this technology. For those wanting to reduce the manual workload and spend more time on what matters most like feeding, pasture management, cow health and reproduction then this technology offers exciting potential.

All brands of machines are equipped with a range of sensors (e.g. electrical conductivity, somatic cell count, blood, fat and protein) that measure milk quality and udder health at every milking. Some brands have the ability to draft cows automatically if mastitis is suspected and/or direct milk away from the main silo. While each cow is not sighted every day, in an automatic milking situation the herd manager has much more information to determine if a cow has mastitis than in a typical conventional system. Experience has shown that as long as the alert reports are routinely checked and acted on mastitis detection is not a difficult task.

Yes. AMS are in-use in over 22 countries worldwide, mainly central Europe (e.g. the Netherlands, France, Denmark, Germany).

The technology is used in farming systems very different from those typically seen in New Zealand. The majority of farms with AMS are housed systems with very high per-cow yields and intensive feeding systems.

No. High-throughput dairies of the present are based on rapid batch milking. Current robotic technology depends on distributing milking over a 24 hr period with a continuous flow of cows through the system.

Yes, it is now very effective technology, but it does take much longer than for a human to do it. The first commercial automatic milking systems were installed in the Netherlands in 1992.

It may take 45 seconds, it may take up to 3 minutes or more, and depends on cow movement, size of the teats and shape of the udder.

The fastest systems will attach all 4 teatcups in approx. 20 seconds once the robotic arm is under the cow. This does not include teat preparation time. For some cows it may take up to 3 minutes, and depends on cow movement, size and shape of the udder.

Yes, some cows are not appropriate for either behavioural or teat size or udder shape reasons. However as technology has improved there are fewer cows are not suited to AMS. Farmers report that a smaller number (1-3%) of cows on the New Zealand farms were not suited and these are identified in the early transition period. Cows with very high back quarters and/or teats that overlap can be a problem for attachments.

Human involvement in the milking process can be much more volatile and irregular than that expected by the cow. The AMS is very consistent and the cows learn what to expect.

People still play a very important role and rather than 'losing contact' with their cows, farmers report that the cows become quiter and they know more about each cow than they did when milking conventionally.

Much effort has gone into automated systems to check for health, heat, mastitis and monitor milk quality.

The systems produce daily alert lists of cows that fall outside the normal range and which should be checked by staff. There is a lot more information available for individual cows than in most conventional milking systems. However, it is critical that the farmers learn how to interpret and work with this data.

In an automatic system, the cow chooses when to get milked.

Yes, farmers report that some cows show a preference for certain robots. This may be related to the AMS they were trained, in a preference for either left hand or right hand entry sides.

Some farmers choose to install a back-up generator, especially in areas where power may be unreliable. If the power is off for several hours there will be a back-log of unmilked cows that can be cleared by changing milking permission settings to prioritise cows. Depending on how long the power cut lasts, it can take a couple of days for cows to settle back into their routine.

Yes, simply select which teats are to be milked using individual cow settings in the software.

There are settings that can be changed using the software which instruct the AMS where to direct each cow's milk. Cows who have been treated with antibiotics and their milk must be kept separate from the main herd, are set to dump or milk is diverted to separate holding tanks.

| Conventional farm | AMS farm | |

| Cow movement | Whole herd moved to dairy for milking | Individual cows move to dairy for milking |

| Milking time | Set by farmer and dependent on farm labour | Cows can access the milking unit at any time. Labour not required to be present |

| Milking frequency | Usually twice a day | Cows can be allowed to be milked more or less frequently to meet the production targets and match stage of lactation |

| Labour - key milking tasks | Labour needed for moving cows to dairy, teat preparation, cups on, cups off, teat spraying, drafting |

Labour needed to fetch the odd 'no show' cow - usually combined with other paddock jobs ie changing fences |

| Labour - cleaning and maintenance | Labour needed for cleaning machines, vats, yards plus regular machine maintenance |

Labour needed for yard cleaning, plus regular machine maintenance |

| Labour - breakdowns | Potential for breakdowns twice/day | Potential for breakdown anytime |

| Labour - pasture management | Calculate feed requirements, assess pasture quality, allocate pasture/move fences, maintain feed pad |

Calculate feed requirements, assess pasture quality, allocate pasture/move fences, maintain feed pad |

| Labour - computer work | May be limited if only paper records are kept | Check alerts, set visitation rights, review daily performance |

There are at least five companies manufacturing and marketing AMS worldwide. At present only two are actively marketing in New Zealand and have established distribution and support networks: Lely Industries and DeLaval.